Best Automation Investments for Precision Manufacturers

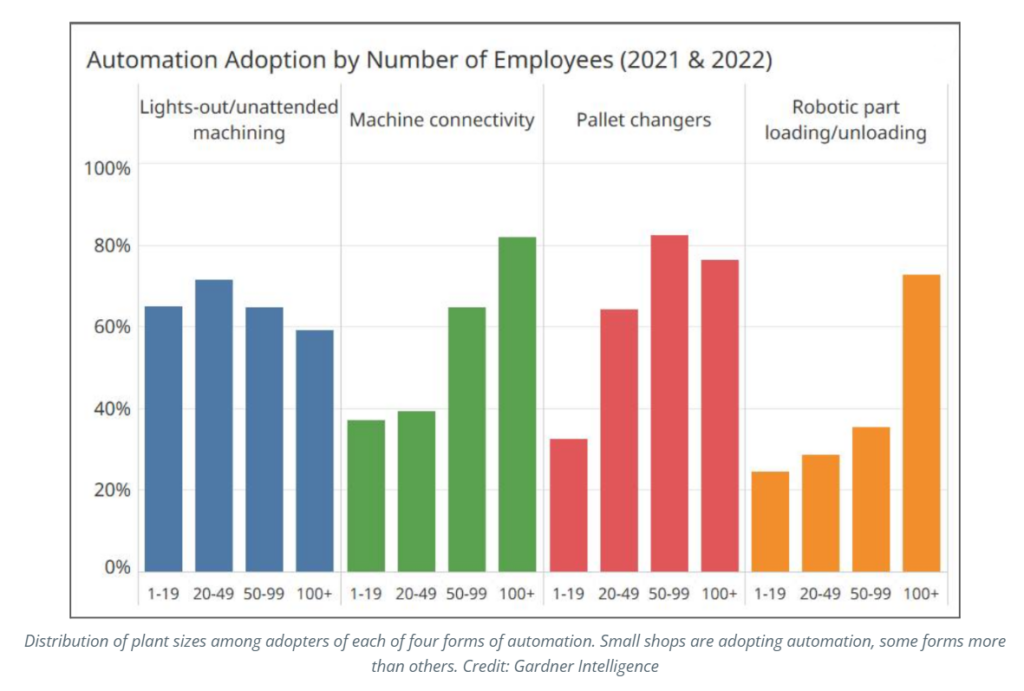

There are a lot of choices when it comes to investing in automation, how do you pick which option will have the biggest impact on your revenue? Let’s look at the top four automation choices US shops made in 2021/2022 according to a Gartner Intelligence study. Below are some pros and cons of each choice with regard to cost, integration, and revenue potential.

Lights-out / Unattended Machining

Lights-out / Unattended machining is when CNC machines are operating with little to no human supervision. Lights-out / Unattended machining saw pretty consistent investment by top shops of different sizes.

- Pros: It’s a great option if you have the right equipment and the right part mix. These types of machines work best for shops supporting industries with steady demand for high(ish) volume parts. It provides significant savings in labor costs and energy costs over time. It can be a work around for the labor shortage on some level.

- Cons: The upfront costs are very high and include setup, training, and implementation. It can be a bad investment for shops with the wrong machine types and/or part mix because a good ROI is very dependent on maximizing machine uptime. If the machine(s) are idle – ouch.

- Impact to facility: Most facilities start small and grow if it is supported by demand. The impact on revenue can range from 1.5 – 5x+ per machine running lights out depending on what machine and if it is just running another shift or really 24/7…

Machine Connectivity – Machine Monitoring

Machine connectivity refers to the networking of machines to enable the exchange of real-time data, monitoring, or control. Datanomix Automated Production Monitoring software is an excellent example. It eliminates the need for people to manually gather and analyze production data to help guide decisions.

- Pros: Datanomix pulls data directly from connected machines, scores and then displays real-time and historical insights across TVs, mobile devices, and dashboards; helping people intervene quickly when issues come up. Low upfront costs and an ROI measured in minutes, rather than months or years, makes this an attractive option for any type of facility. The software is compatible with all modern makes and models of CNC machines and customers see double-digit improvements in utilization. Rich data available includes touch time, cutting time, TAKT, tool usage, benchmarks, and more.

- Cons: Highest value gained by shops with ethernet-connected CNC machines. Requires facilities to embrace using data to drive decisions. Modern software platforms are Software as a Service (SaaS) model.

- Impact to facility: Conservatively, shops gain an additional hour of uptime per connected machine, per day.

Pallet Changers

Pallet changers also saw significant investment in all but the smallest of shops. They allow for the automated movement of raw or finished parts to and from the machine to reduce the downtime from manually loading/unloading the machine.

- Pros: Increases productivity, efficiency and quality by leveraging an automated process to reduce the need for manual labor. Pallet changers can also include tool storage and management systems, ensuring that the right tools are available for each job, which further reduces setup time.

- Cons: High initial Investment is required for both equipment and integration with existing machines. Some of these systems can take up significant floor space which means you might have to reconfigure your production floor layout. Ongoing maintenance costs can be significant because they require more regular maintenance due to the increased runtime. The ROI window for pallet changers really depends on production volume, part complexity, and the machine’s utilization.

- Impact to facility: 3-5X or more improvement over a standard machine per system. Some types of systems can even be higher, but costs are also higher and physical footprint large.

Robotic Part Loading and Unloading

Collaborative Robots (Cobots) work alongside operators doing repetitive or strenuous tasks like pick-and-place actions.

- Pros: Cobots don’t get tired and can do specific tasks with high precision, improving overall production output. Most cobots are flexible and can be reprogrammed for automating different parts. They also reduce labor costs in the long run. Can be leveraged to implement lights out manufacturing.

- Cons: High upfront costs, including buying the robot, end-of-arm tooling, and integration into existing systems. Programming and configuring cobots for specific tasks can require significant technical expertise, and the learning curve can be steep for existing employees trying to take on this role. ROI really depends on the application, so it is important to do your homework.

- Impact to facility: 1.5-3x per machine equipped with cobot/robot

When to Invest in Automation?

Ultimately, the decision on what type of automation to invest in should be based on a long hard look at your manufacturing goals, available resources (both monetary & human), and the competitive landscape.

Many manufacturers combine automated machining technology with Datanomix Production Monitoring to optimize these new technologies (and existing machines) because the ROI for all automation investments depends on maximizing efficiency. It is difficult, if not impossible, to analyze the efficiency of new automation technologies manually or with an ERP system.

Check out our interactive calculator to see which technology would give you the biggest bang for your buck.