Predictive Tool Life

Accelerate Job-Level Continuous Improvement

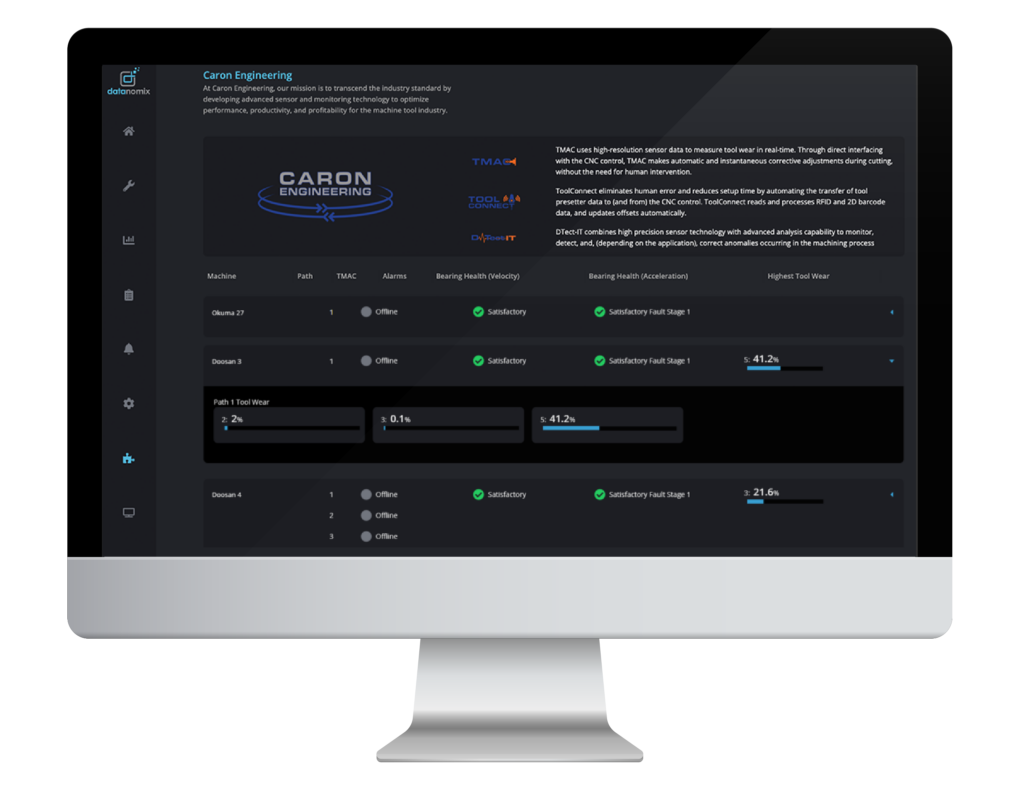

Datanomix + Caron Engineering

By integrating and analyzing Caron Engineering tool performance and optimization data, Datanomix delivers more profound insights, giving you visibility from the tool to the machine to the overall factory.

Caron Engineering has been delivering intelligent manufacturing solutions since 1986. By combining decades of manufacturing domain expertise with advanced sensor and monitoring technology, Caron optimizes performance, productivity, and profitability for precision manufacturers. The Datanomix TMAC dashboard represents the first offering from the integration between Caron Engineering and Datanomix. The Datanomix data science team is currently analyzing Caron performance data to create new machine learning algorithms that will deliver deeper insights, from the tool to the machine to overall factory production.

Proactive Maintenance & Predictive Tool Life

A Datanomix dashboard displays the status of every TMAC-enabled machine in the factory, providing a consolidated view of performance that accelerates job-level continuous improvement. The dashboard shows Caron’s performance parameters, including each TMAC machine’s horsepower, vibration, pressure, strain, and coolant information. Users can create alerts for out-of-tolerance conditions, enabling rapid response. In addition, the dashboard provides a quick view of Bearing Health and Tool Wear to empower proactive maintenance.

“With Datanomix, we are bringing advanced data science to our customers, extending insights past tool optimization to overall machine performance and beyond.”

Rob Caron, Founder & President

Caron Engineering