Make More with Data-Powered Production™

Hit Dates. Cut Waste. Stop Guessing at Profits.

Real-time visibility meets factory floor execution with tools and coaching to unlock profit fast. We don’t sell dashboards. We sell outcomes that help manufacturers Make More.

We Cut Wastes that Typically Cost Manufacturers $1,000’s in Profit Every Day

What’s Stopping You from Making More?

Flying Blind on the Production Floor?

Downtime creeps in. Delays go unnoticed. Hours, jobs, and margin are lost.

YOU NEED

Production Monitoring

- Automated Part # and Job Tracking – right from the machine

- True Cycle Time + Part Count Insights with Cutting & Touch Time Benchmarks

- Automated Setup & Changeover Detection

- Automated Downtime Insights + OEE

- No Operator Input™ Required

- Notifications for Key Production Issues

- Accessible via Web, Mobile App, or TV App with Unlimited Users

Scheduling & Forecasting Struggles?

Jobs run late. OTD suffers. No one knows where to put the next job.

YOU NEED

Planning + Job Tracking

- On-Time Delivery predictions

- Auto-sync with ERP: Work Orders, Quantities, Due Dates

- Clock-in/Clock-out Automation

- Compare labor utilization vs. machine time and output

- Highlight what’s at risk before it derails your schedule

Leaving Real Money on the Table?

Some jobs win, some jobs lose, but which ones are hurting the bottom line?

YOU NEED

Quote/P&L Analytics

- Automated part-level profitability analysis

- Surface hidden winners and silent killers

- See job costs, labor costs, and real machine time tied to every quote

- Find high-margin work to make more of

- Identify where to raise prices or walk away

- Enhance Reporting with ERP Insights

ERP Not Reflecting Reality?

Data’s delayed. Job status is unclear. Decisions get made on guesswork, not facts.

YOU NEED

ERP Insights

- Compare actual machine performance to ERP expectations

- Find the lost hours that are hiding in plain sight—and take them back

- Forecast completion dates based on actual progress, get early warnings when jobs fall behind, and take corrective action before customers are impacted

- Works with both cloud-based and on-prem ERP systems

Contracts Requiring CMMC 2.0?

Revisions go missing. File changes get lost. Compliance is at Risk. Machines and people sit idle.

YOU NEED

G-Code Cloud™ + DNC

- Gov-Cloud-native, ITAR-compliant G-Code and Production File Management

- Manage, Approve, and Edit G-Code Files Right from Your Browser

- Integrated DNC functionality

- Fully CMMC 2.0 Compliant

- Digital Work Instructions, Setup Sheets, Tooling Sheets, 3D Models, and more!

Improvement Projects Standing Still?

Tools run out. Cuts go off spec. Cycle times drift. Scrap/rework sneak in. Costs creep up.

YOU NEED

TMAC ai™ + Tool Insights

- Automated TMAC Limit Setting

- Tool Life + Cycle Time Optimization Recommendations

- Detect Process Changes and Predict Scrap Parts Using Real-Time Cutting Data

- Tie Tool Performance to Actual Cut Signatures and Part Revisions

Why Data-Powered Production™?

Whether you have no data, bad data, or just had your ERPiphany — that moment you realize error-prone ERP data won’t give you the answers you need to Make More — Datanomix delivers production-ready visibility and profit-driving outcomes from day one.

The Missing Link for Most Manufacturers?

Ground-truth machine data—and the power to act on it. Too many shops are stuck in spreadsheets, relying on outdated ERP reports, and using disconnected tools. Datanomix is How You Leap Forward.

With the right Platform, a clear Plan and real People alongside you, most shops see a 15%+ output boost within the first 30 days.

You can call us Machine Monitoring, MES, or Production Intelligence — honestly, call us whatever you’d like. We offer total victory for any manufacturer determined to Make More by solving problems and delivering results.

And yes, we use AI—along with whatever it takes to help you win. Because manufacturers care about outcomes, not acronyms.

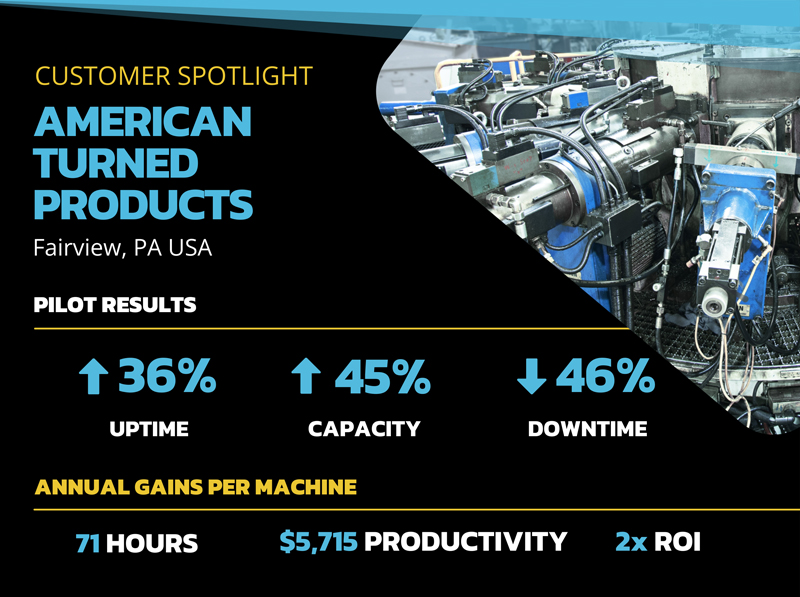

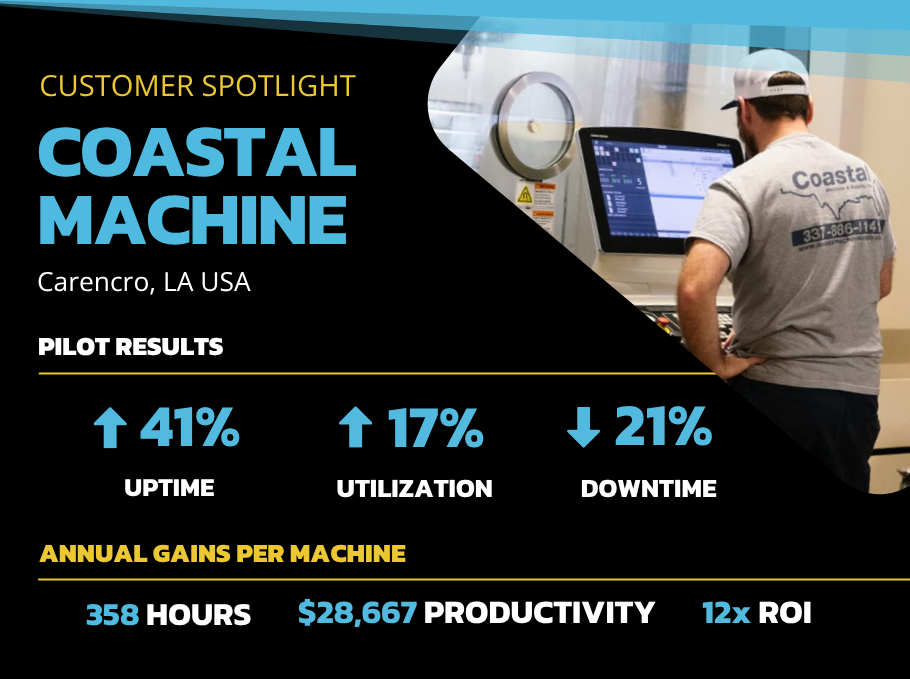

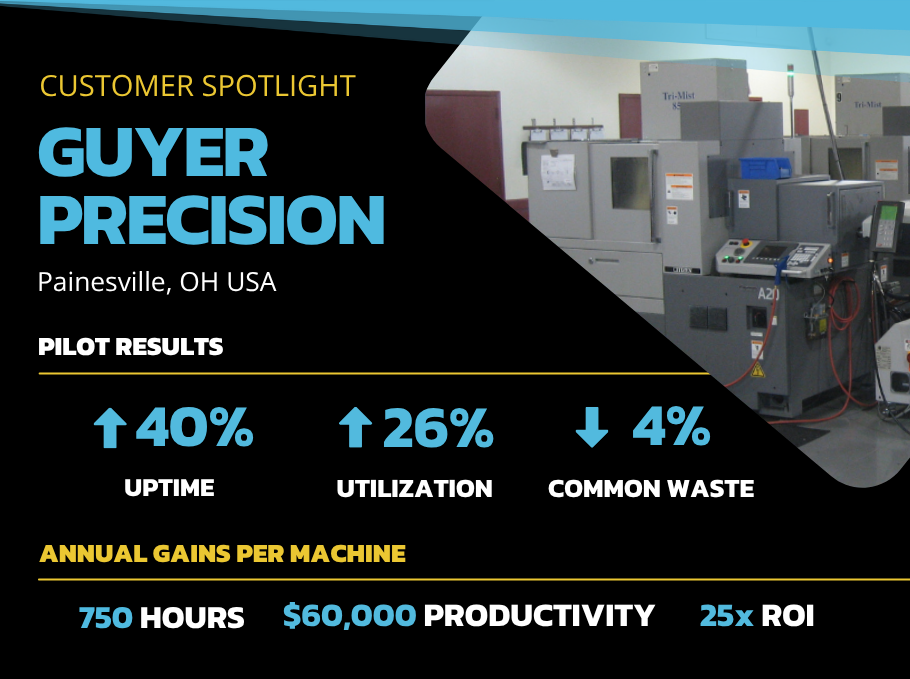

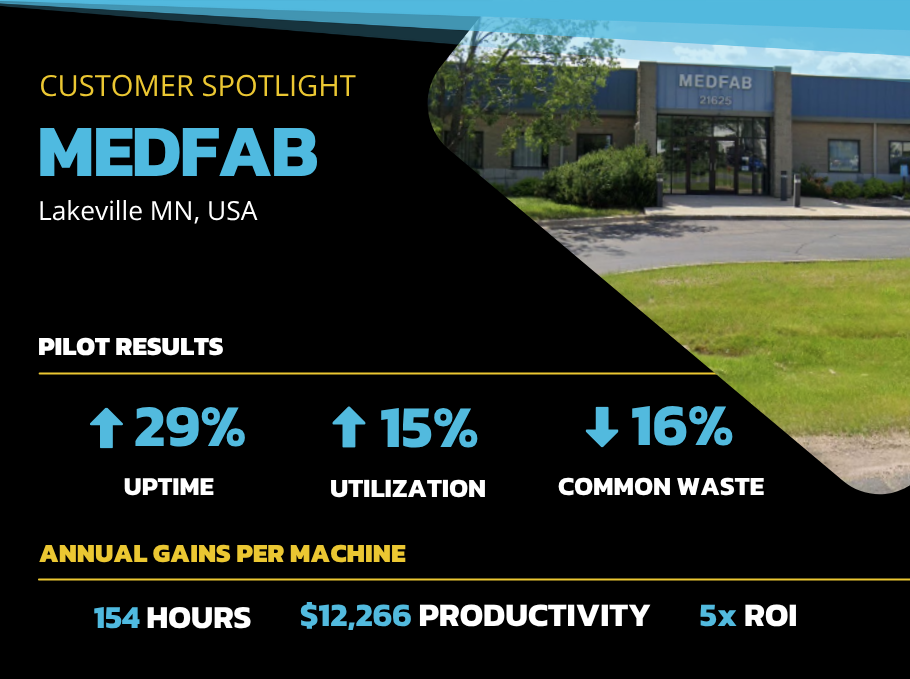

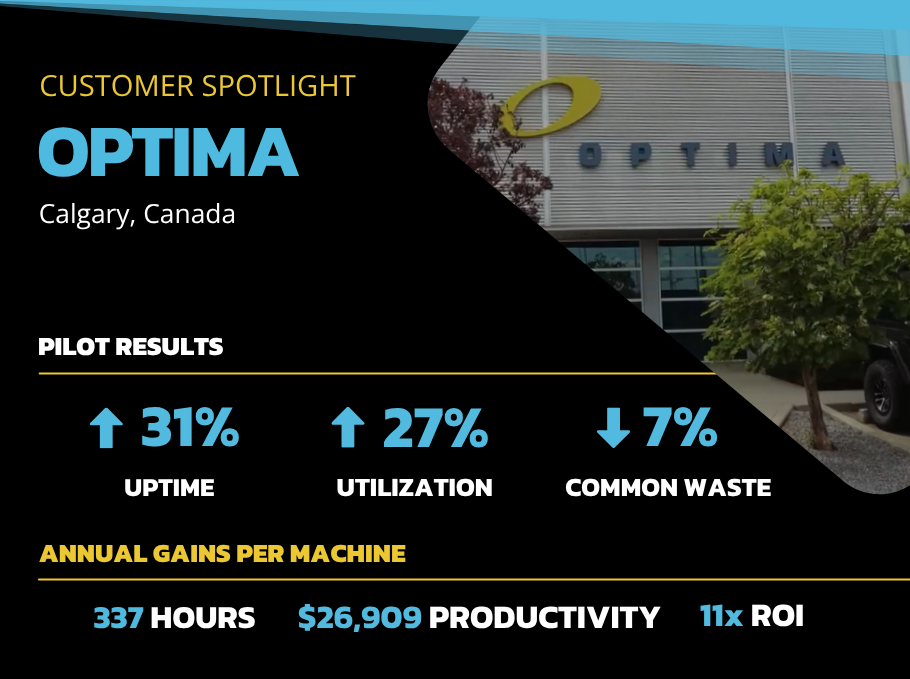

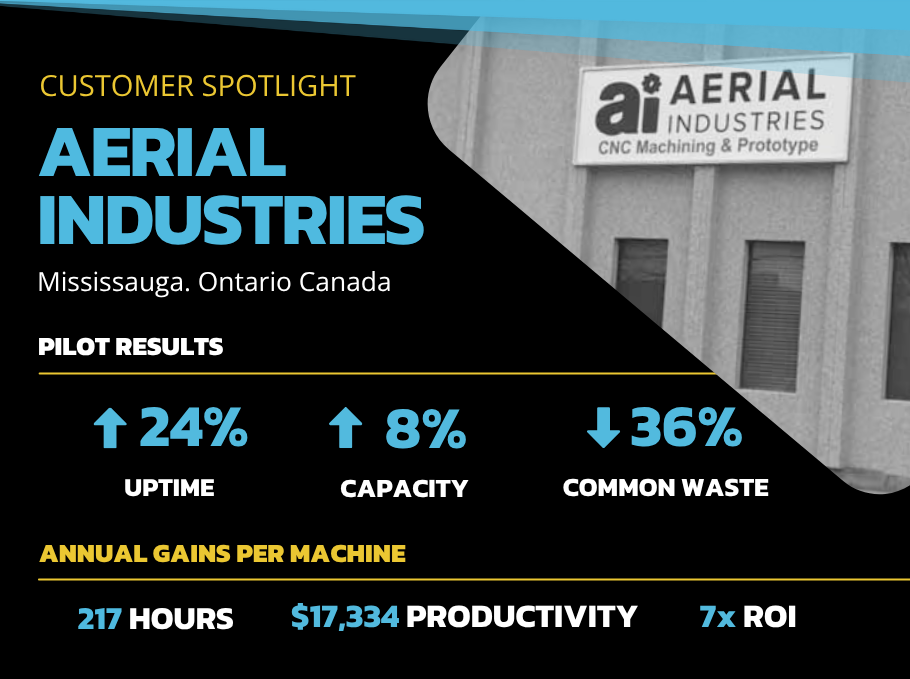

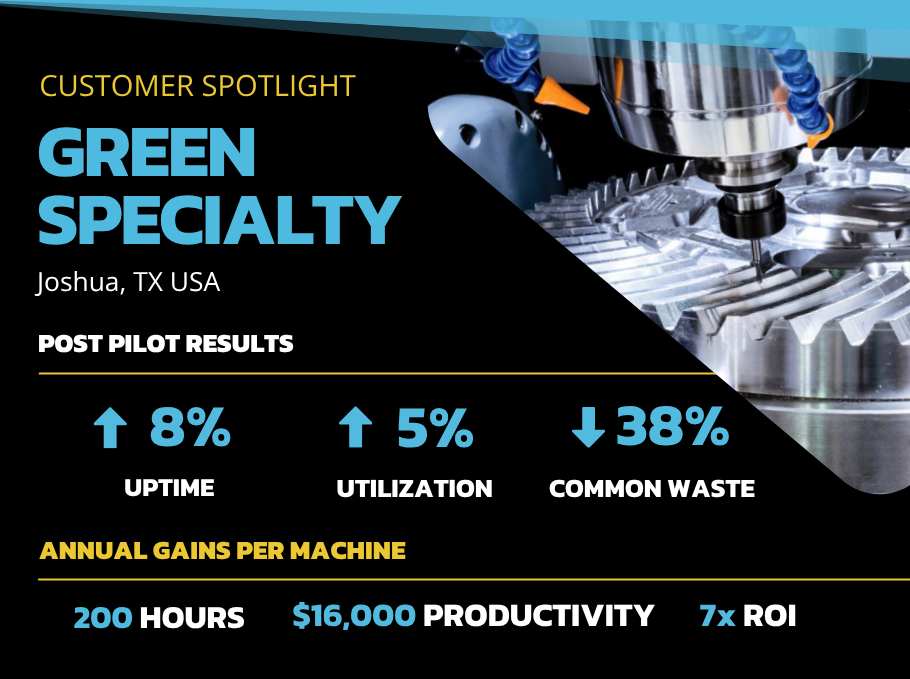

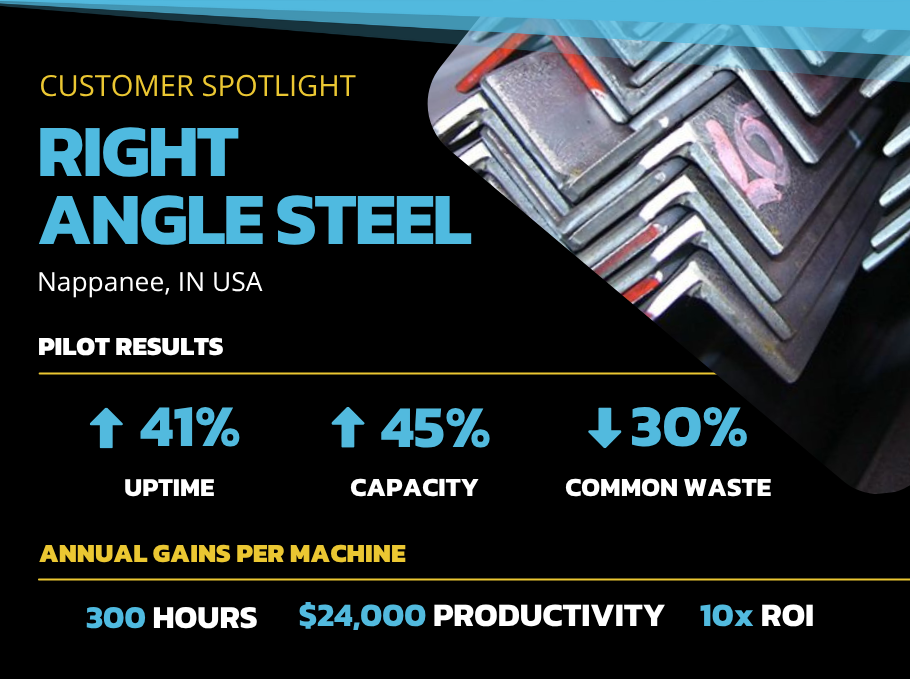

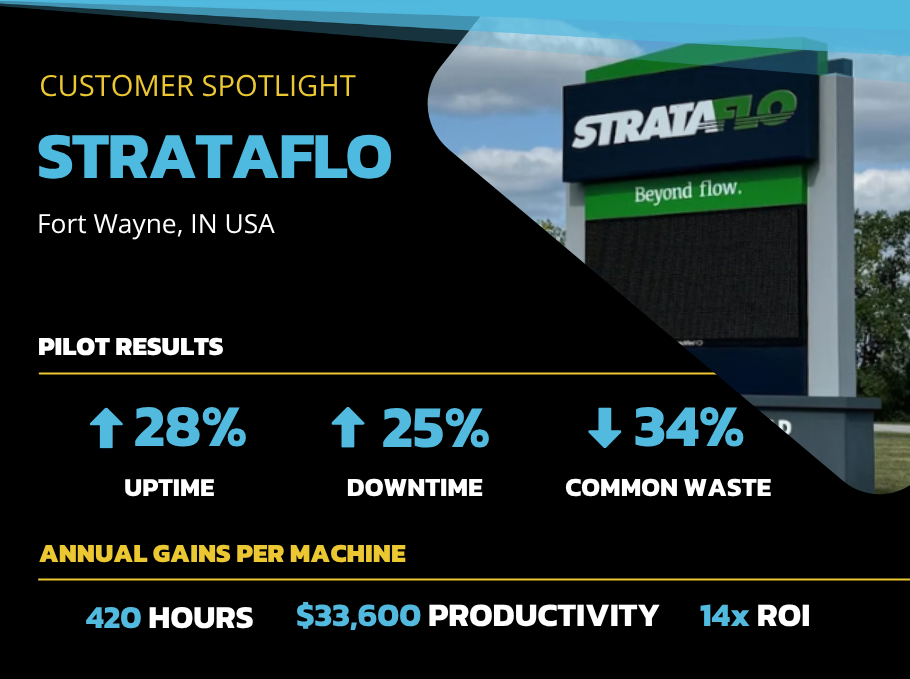

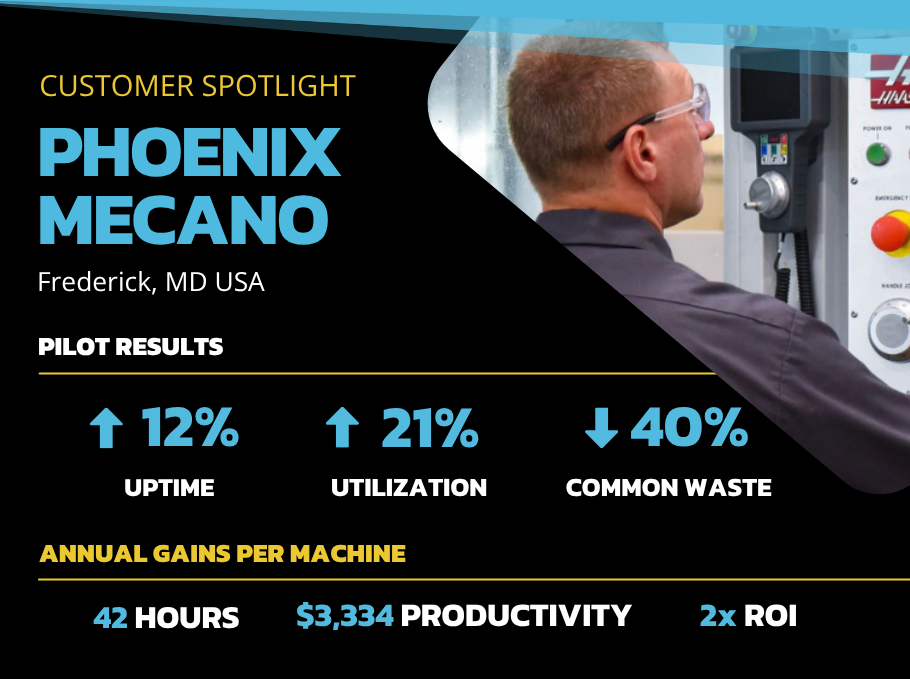

Proven Results

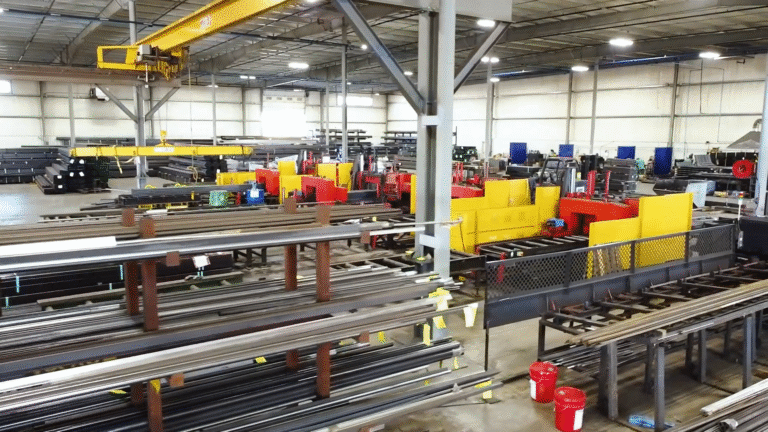

Connects to All Major Makes and Models of CNC Machines, Fabrication Equipment, & More

Built for Any Shop. Proven in Every Industry.

Whether you’re a high-mix job shop or a high-volume OEM, Datanomix delivers the visibility manufacturers need to drive more output, boost margins, and make winning decisions.

Hundreds of shops are already seeing the impact. Real results. Real momentum. And a growing community of manufacturers committed to Making More.

Paramount Machine Makes the Switch to Datanomix Production Monitoring

After years of struggles with their prior machine monitoring system, Paramount finds no-nonsense, out-of-the-box value in Datanomix.