Automated Job CostingTM

Know Exactly How Much it Really Costs to Make Each Part

Do You Know If You’re Making Money?

Every manufacturer wants to make money on the parts they are producing. A lot of effort goes into the quoting process to make sure that all costs are accounted for and a reasonable margin is added as profit. For many precision manufacturers accurately quoting jobs can be challenge because they don’t know all their costs until after the job is run. That’s because the time it takes to make each part can vary – even on highly automated machines. To compensate, a “fudge factor” is added to a best guestimate which is based on historical data or tribal knowledge. This estimate is added to the ERP to generate the quote. Because of the production information in the ERP are estimates, manufacturers don’t know how much (or even if) they made money until after the part ships. That’s a tough way to run a business. There has to be a better way.

Datanomix + ProShop ERP = Accurate Quoting

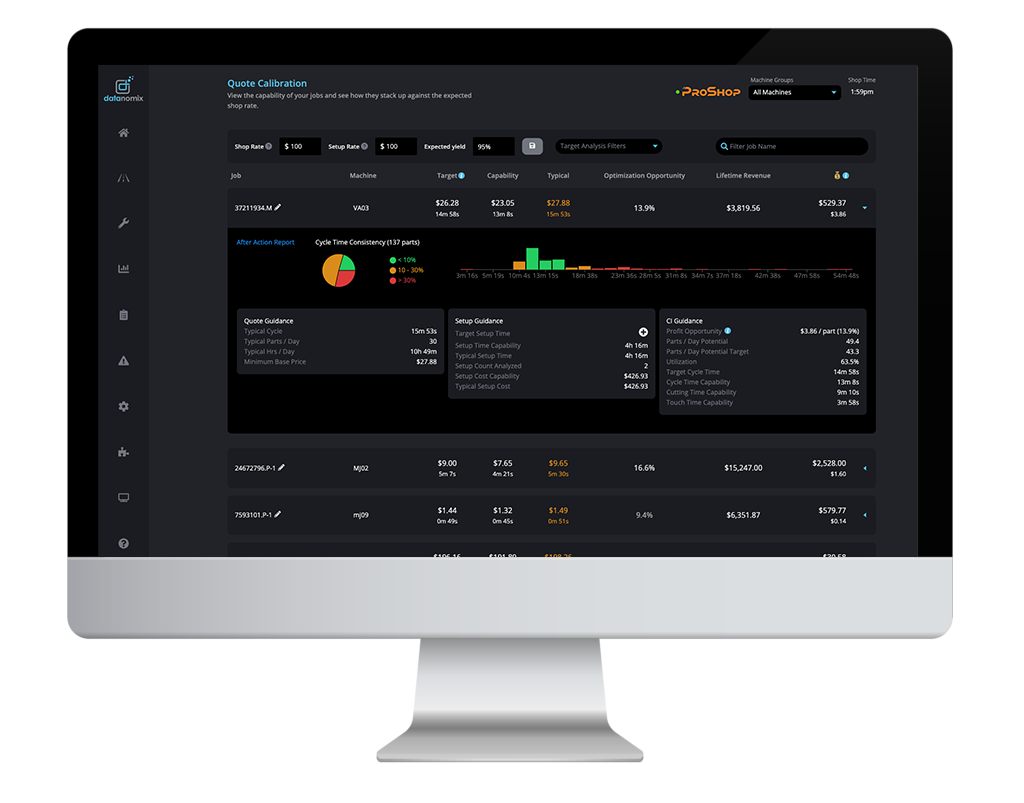

The integration between Datanomix Production Monitoring and ProShop ERP replaces estimates with actual data to make creating accurate quotes effortless.

How it Works

The seamless integration automatically matches part numbers between Datanomix and ProShop and extracts the target takt times. The target is then compared to actual machine performance in Datanomix. Any variance in button-to-button time, cutting time, and touch time is displayed and a letter grade of A+ to C- summarize how the job is performing overall compared to plan. This enables production to focus on jobs that are underperforming.

Automated Job Costing™

ProShop targets are integrated into the Datanomix Quote Calibration Report to quickly help you identify opportunities for improvement. The two-way integration feeds Datanomix real-time production data back into ProShop so you can make more accurate estimates.

Making More Money

The Datanomix Production Monitoring and ProShop ERP integration shows you:

- Winners – part numbers that beat your ProShop targets and are making more profit than anticipated

- Losers – part numbers that did not beat your ProShop targets

- Winners with Upside – part numbers that are beating your targets but could be making more money

- Losers that Could be Winners – part numbers that Datanomix has seen you run well enough to make it a winner

“Connect us up to your machines, let our software do its magic, and it will come up with performance standards and actuals on its own. Hook us into your ProShop ERP instance, and you’ll get automated analysis on exactly which part numbers you need to be focused on from a job costing and margin improvement standpoint.”

Greg McHale, Founder & CTO

Datanomix