Manual Versus Automated Monitoring

It’s Not Even Close

Manually collecting data about machine downtime, cycle times, or the number of parts produced is time consuming and often inaccurate. The data is always collected after the fact when it’s too late to change anything. The best you can expect is a well-maintained board with paper graphs and charts that show yesterday’s numbers.

Automation is the way to go. All modern CNC machines have sophisticated controllers that track and record real-time data on their performance and output. Datanomix Production Monitoring software collects all that raw data and analyzes and scores it in real time. Actionable insights are then instantly available to operators, supervisors, and managers. They can see exactly where they should focus RIGHT NOW to optimize efficiency.

“If you’ve got 20 machines, 50 machines, 100 machines, how do you send somebody around with a stopwatch to time every single tool, every single cycle time, on every job running on every machine? … What we’re getting out of Datanomix machine monitoring is a level of accuracy and granularity that you just couldn’t pay somebody enough to go and get.”

— Kylan Hastreiter, Vice President, Hastreiter Industries

Which Automated Monitoring Solution You Choose Matters

Automating the collection of data isn’t enough. You need the out-of-the-box insights that help your people make the best decisions, improve a process, meet a goal, save time, etc. Monitoring solutions that just gather data and spit it out are even worse than manual systems. Now you are paying someone to do a job – and they are not delivering.

“So not only do I have to be my own data analyst, I have to be the data engineer to actually even create the whole system. Even though I’m paying these guys to create the system for me. Sometimes what looks really good on the outside isn’t necessarily what is actually on the inside. And with some of those issues, if we would have just started with Datanomix, we’d never even known that those were even potential issues to have in the first place.”

— Kylan Hastreiter, Vice President, Hastreiter Industries

Real-Time Visibility Drives Real Results

Operators benefit from knowing the real-time data on how the current job running on their machine. Datanomix TV Mode displays LIVE information around Utilization, Cycle Times, down machines, and leaderboards for Time on Tap. With the new Goal Setting functionality, all the data is color-coded to reflect how it compares to the set goal. All this real-time information makes it’s easy to monitor how every machine is performing. When there is an issue, operators don’t have to take time away from fixing the problem to input what they are doing and why. They can just focus on the taking care of the issue. No Operator Input™ is part of Datanomix DNA—we even own the trademark!

In addition to seeing live data on TVs, designated people on the team can get notifications on their mobile device and via email when specific issues occur or go on too long. Use cases include on-call person’s phone blowing up when a pallet machine goes down at night, supervisors knowing when a Program Stop has not been cleared for 30 minutes in their cell, and managers notified when a machine making a critical part is down for over an hour. Datanomix helps ensure that the right people, have the right information, at the right time. This is impossible to do with manually collected data.

Does knowing where to focus in real time help manufacturers make more money? Yes. The average Datanomix customers sees double digit growth in their utilization rates. See the potential impact to your shop on this ROI calculator.

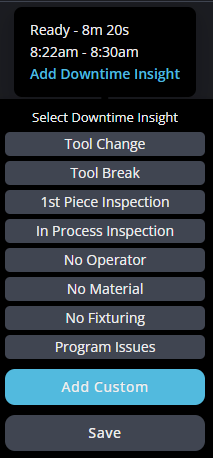

Capturing Operator Insights

Manually capturing operator input involves either writing down details in a notebook or tapping them into a tablet. In Datanomix, there are also multiple ways to capture operator insights. Operators can click into the machine’s utilization timeline and select from a list or customize. Operators can use their mobile device or existing tablet to add information in real time. No second tablet (and the IT headaches that come with them) required.

There is also a Notebook function where operators can add notes about issues they had during a shift or ideas for improvement. It replaces the paper notebooks often found at machines and takes away the need to be able to read people’s handwriting. Data entered either way is automatically tied to the machine, job, and time and available to the team.

Get the BEST Automated Production Monitoring System

Datanomix provides precision manufacturers with the real-time and historical insights they need to maximize uptime, optimize part profitability, and grow. No Operator Input™ required! Other automated monitoring systems are either too simple to be effective or too complicated to be practical. Many claim they don’t require operator input, but customers who switched tell us wasn’t their experience.