Optimize Cycle Times

You’re making parts, but are you making money?

MAKE MORE PROFIT

Maximizing your uptime every day is fundamental to improving production performance—and to the Datanomix platform. But utilization is just one piece of the puzzle. Improving cycle times is really what increases profitability. That’s why the Make More Profit module of Datanomix Production Monitoring software provides accurate time studies for every part, on every machine, every day—without requiring operator input. Now, you can see the actual cutting and touch time to uncover areas that can be improved.

Get immediate answers to important questions like…

- What’s the cutting & touch time for every part? Where can we improve?

- How did every part on every machine perform yesterday?

- Which parts are most profitable? Where are we leaving money on the table?

- What parts do we need to re-quote, stop making, or make better?

- What machines are down right now? Why? And for how long?

- What issue is hurting my utilization the most? What can my team do right now to fix it?

We’ve got your back every step of the way!

Look, change is hard, even when the software is as easy to use as ours. When you partner with us, you get a dedicated Customer Success Team that works with you to customize the three phases of your software rollout and the associated training.

PHASE 1: QUICK WINS

Every new customer starts out with three Quick Win workflows. These deceptively simple first steps get every employee engaged with using real-time data and have an immediate impact on efficiency.

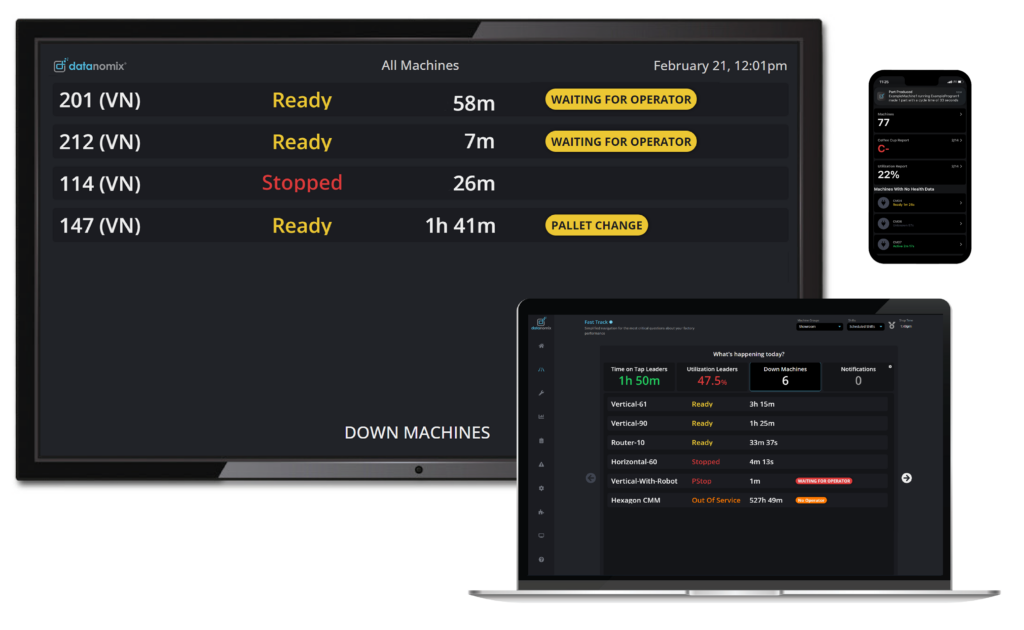

1. Down Machines

TVs display every stopped machine, why it’s stopped, and for how long.

2. Real-Time Notifications

Alerts sent to mobile devices that show operators & supervisors where their attention is needed.

3. Time On Tap

Tracks and displays the time it takes to get machines into cycle, downtime around breaks, and the time between last active and end of shift.

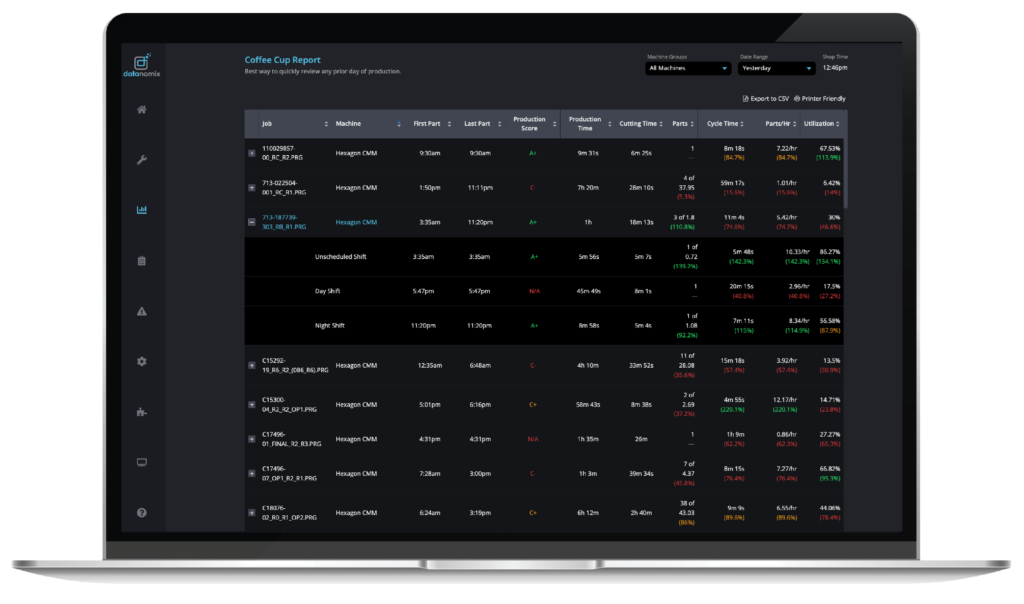

See How Every Facility and Every Part is Doing with the Datanomix Coffee Cup Report

Every morning at 6 a.m., an automated report called the Coffee Cup Report is emailed to the team. It is a simple scorecard of end-of-day and end-of-shift performance by job. The report provides the data needed to run an informative morning production meeting and quickly update the leadership team on the previous day’s work.

PHASE 2: SETTING GOALS

After the initial bump in efficiency from the Quick Wins, your dedicated Customer Success Team will meet with your managers to set goals and track deviations using:

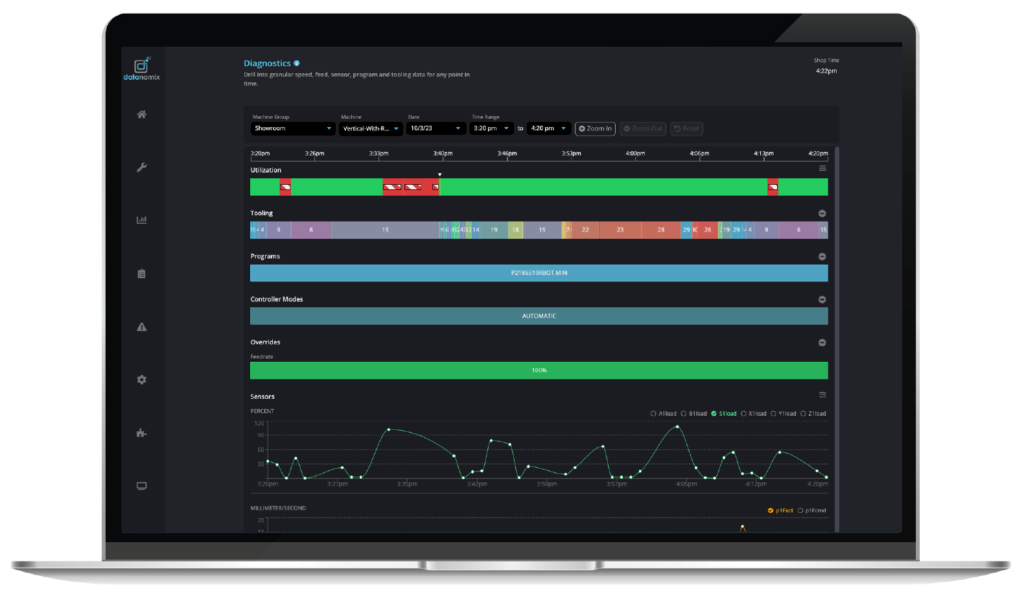

Machine Diagnostics

Drills into granular speed, feed, sensor, program, and tooling data for any point in time

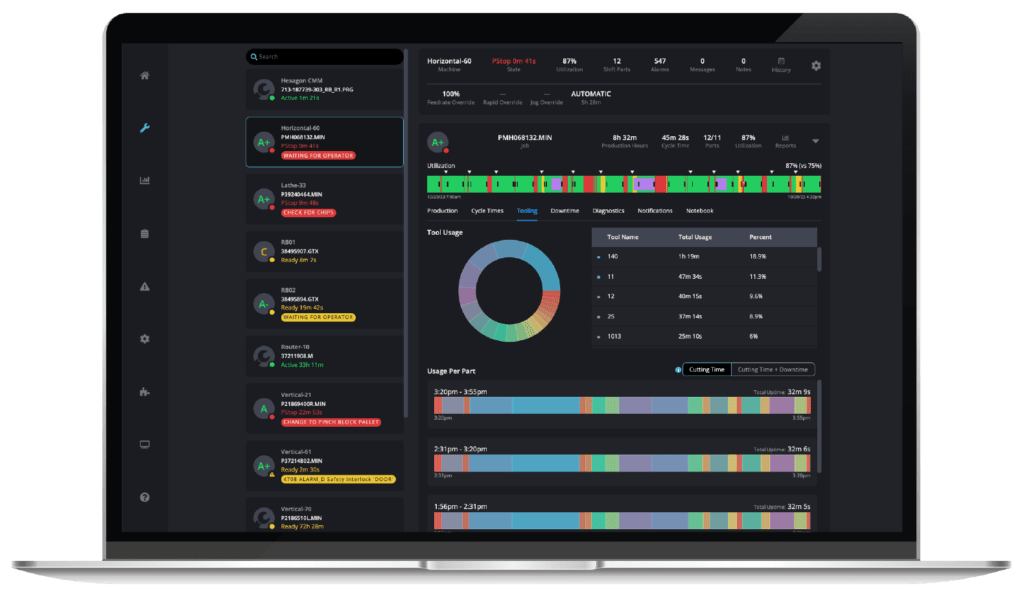

Tool Usage Data

Analyzes how long each tool spends in cycle to reconcile your cutting times, both in aggregate and per tool.

3. REPORTING & CONTINUOUS IMPROVEMENT

In the third phase of training, your shop’s leadership team will learn how to track KPIs, validate improvements, and identify risks and opportunities to profitability goals. To ensure ongoing success, customers always get access to unlimited support, software updates, and online training.

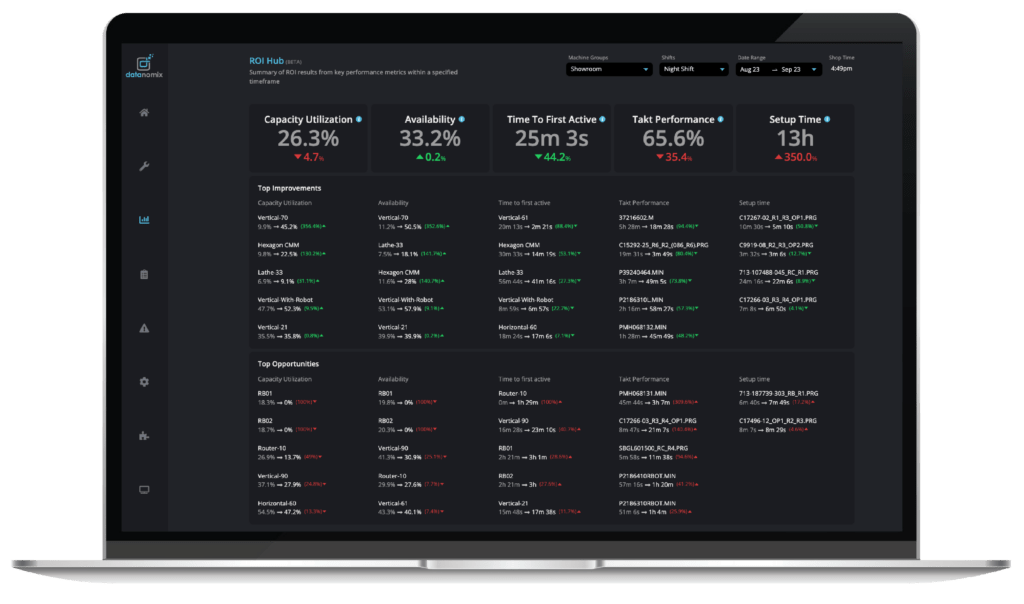

ROI Hub

Summarizes the return on investment (ROI) results from key performance metrics within a specified timeframe.

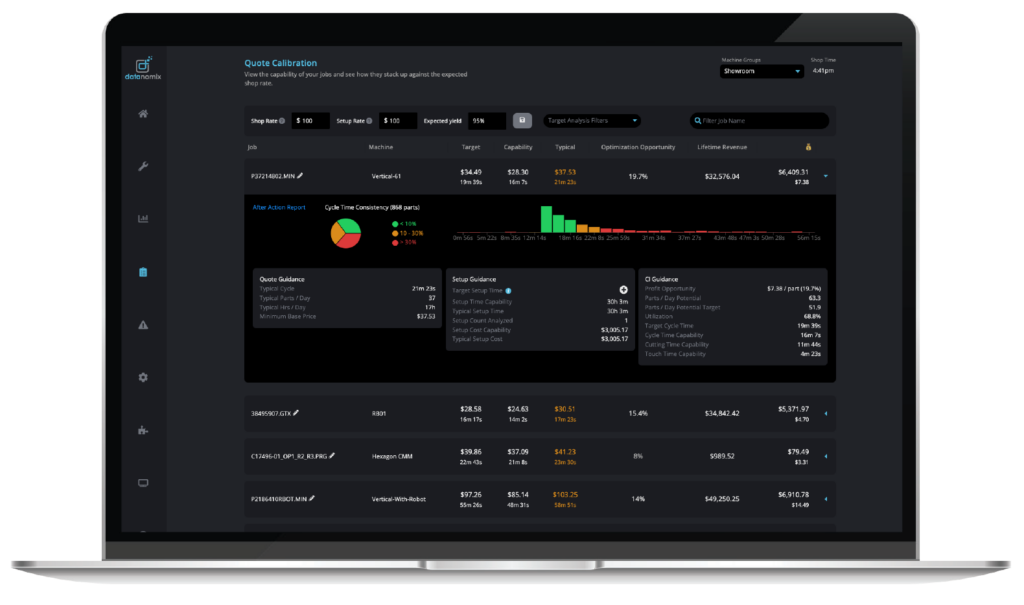

Quote Calibration

Shows the capability of your jobs and how they stack up against the expected shop rate.

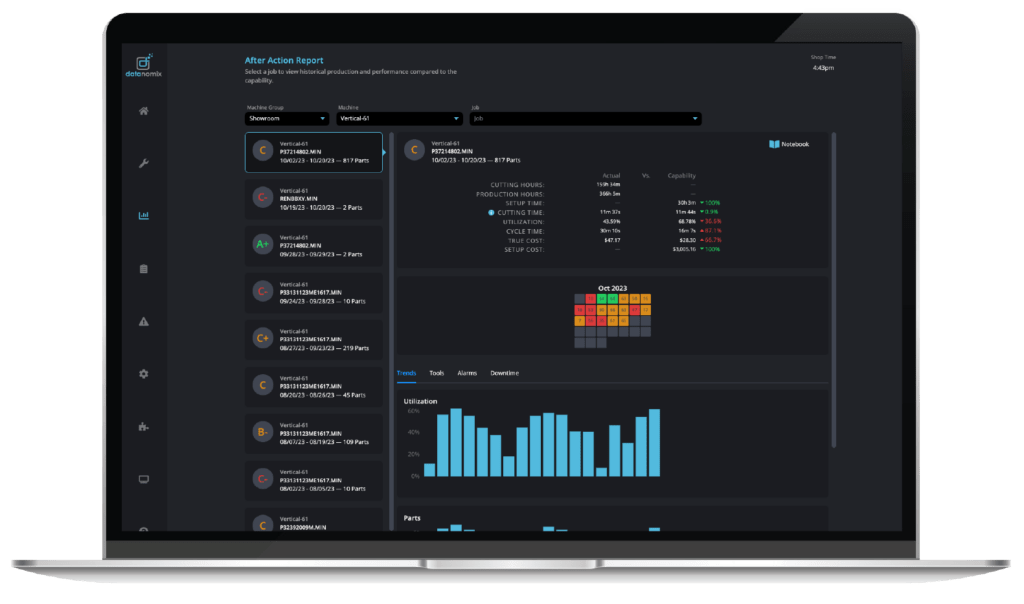

After Action Report

Shows historical production and performance by job, compared to the capability.

Do You Want More?

Unlock productivity, streamline operations, and energize growth.

Request a demo today.