Delivery Track for Predictive OTD

Set production targets for jobs, uptime, or part counts and see your progress in real time

CLOSING THE GAP BETWEEN SCHEDULING AND REALITY

On-Time Delivery (OTD) is the goal of every manufacturer. It’s easy to calculate your OTD once the parts have shipped, but knowing how you’re doing while the job is in process can be a challenge. Often there is a discrepancy between when you planned for the job to be done, and when it actually is. Does this sound familiar? This phenomenon is especially true at job shops that run parts across multiple days, OEMs, and cell-based manufacturers. The extended time frame, quantity of parts, or the number of machines involved makes it difficult to accurately track and forecast jobs. To solve this problem, Datanomix added predictive OTD functionality to our Production Monitoring software.

On-Time Delivery

Delivery Track is a powerful set of dashboards that visualize your scheduled OTD targets and predicts completion dates updated in real time. Knowing exactly when a job will be done, given the current rate of production, gives you time to intervene where necessary.

Key Benefits

- Flexible Tracking Options

Track delivery by job, uptime, or parts to suit your facility’s needs. Use any combination of the three methods based on your needs. - Real-Time Progress Monitoring

Check-in daily to see what jobs/machines are behind schedule and click to to drill into daily and shift performance details. - Improved Resource Allocation

Focus time and resources on the most critical areas to optimize OTD - Enhanced Visibility and Communication

Datanomix is the centralized source of accurate information to track progress and get everyone on the same page - Customizable Goals and Targets

Set part count, completion date, and uptime targets to align tracking with your customer’s requirements

Track On-Time Delivery Three Ways

Most shops have a variety of machine types and processes running at the same time and will find it useful to track them using different methods. Use any combination of the following three methods:

- Delivery by Job

Set target complete dates and part counts for each job currently running on your machines. - Delivery by Uptime

Set targets based on total weekly uptime for each machine. - Delivery by Parts

Set targets based on part count from numerous machines.

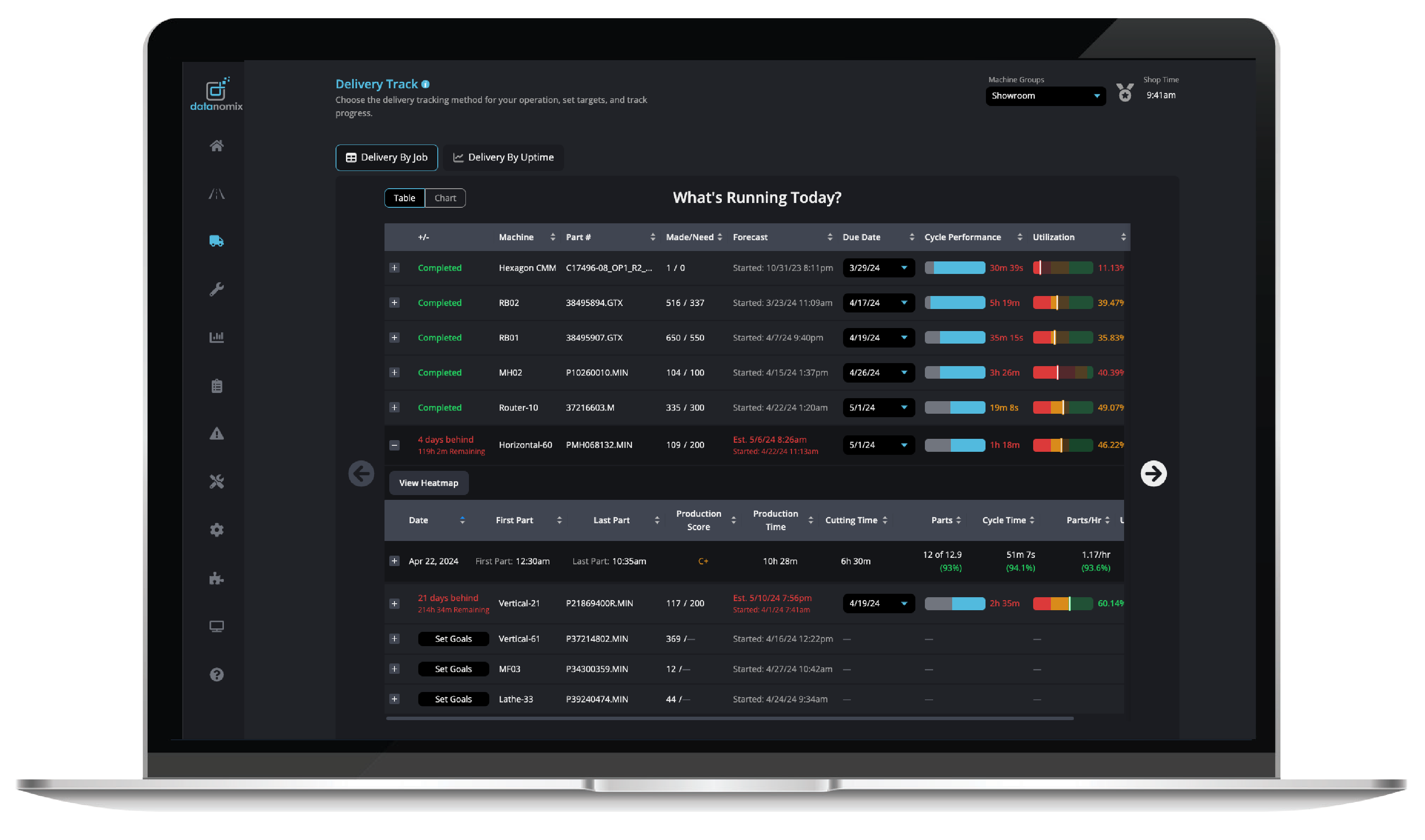

Delivery by Job

The Delivery Track by Job dashboard auto-populates running jobs and displays due date and quantity based on input from the program, your ERP, or data input.

Target part counts and completion dates are displayed against actuals so you know what will be done by when. Projections are dynamically updated as the job progresses. This shows if you are ahead or behind based on cycle times for the completed parts and the number of parts remaining.

Answers These Questions:

- What jobs are running on what machines today?

- How many parts have we made so far?

- How many parts do we need to make in total?

- When are they due?

- Are we on target?

- What’s the cycle time?

- What’s the utilization rate?

- What jobs are in setup?

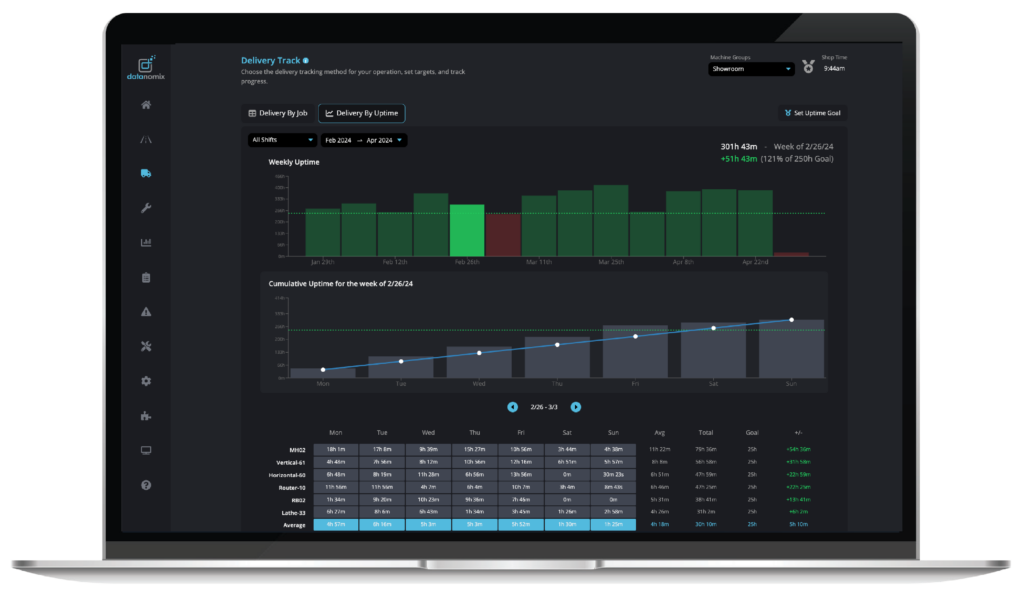

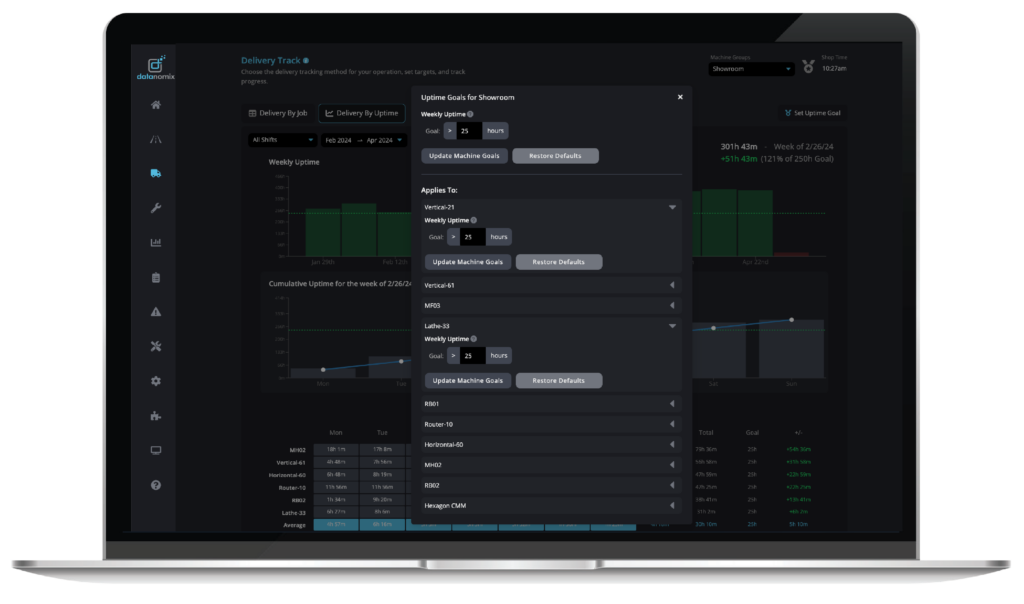

Delivery By Uptime

Delivery Track By Uptime starts with a goal of how many hours of uptime per week you need to “deliver”. Uptime goals can be set for a machine group or an individual machine. This approach is optimized for OEM’s or highly automated facilities where hitting a certain number of uptime hours equals hitting production targets.

Datanomix provides you with a burn-up chart and projection of when you will hit your uptime target. This gives you the visibility you need to make the best decisions around needing a second shift or additional unattended time.

Answers These Questions:

- How are we performing this week vs. our target uptime goals?

- How does this week compare to prior weeks?

- How well have we historically done hitting our Uptime target?

- What day will we hit our target Uptime if we continue at this pace?

- What machines have opportunities for improvement?

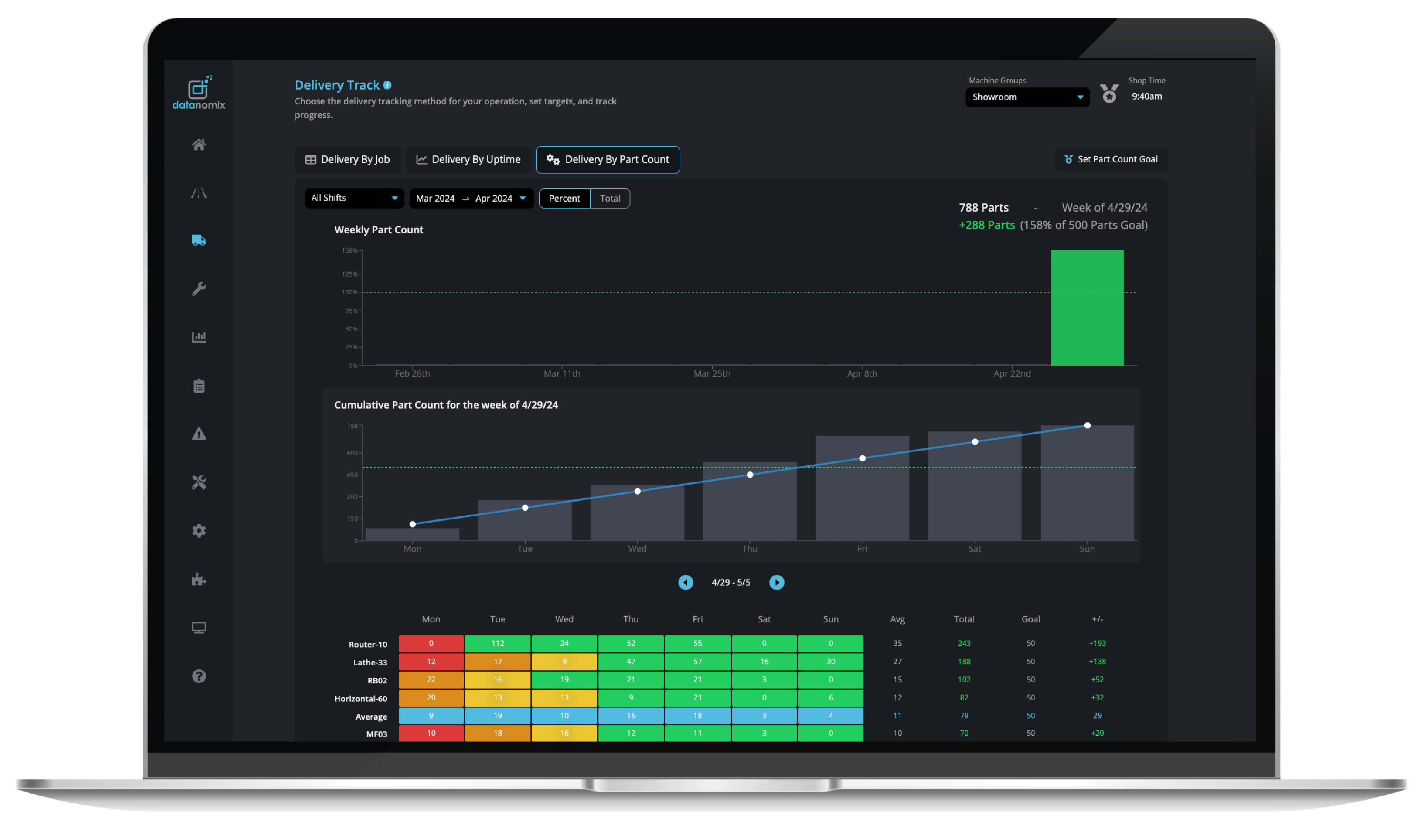

Delivery By Part Count

Delivery Track by part count starts with setting a goal of how many parts a cell needs to produce in a week-based timeframe. Typical customers who love this are firearms’ manufacturers and other OEM-style facilities where several machines in a cell are dedicated to the same part number at the same time. Datanomix shows a burn-up chart and projection of when you will hit your target at the current rate of production. This gives you the visibility you need to make the best decisions around needing a second shift or additional unattended time.

Answers These Questions:

- How are we performing this week vs. our target part counts?

- How does this week compare to the prior week?

- How well have we historically done hitting our part count target?

- What day will we hit our target part count if we continue at this pace?

- What machines have opportunities for improvement?

- How many parts have been made?

Being Predictable Equals Being More Profitable

Datanomix is firmly committed to helping manufacturers solve their most pressing business problems related to production. When our customers asked us to help them with one of their biggest headaches, unpredictable OTD, we created Delivery Track. Improving OTD means you will have more happy customers paying on time and coming back again and again. And, Delivery Track also slashes your Tylenol bill.

Curious to see how different functions at your company will use Datanomix to drive daily decisions?

Datanomix ROI Calculator

Calculate How Much More Revenue You Can Get with Datanomix

Do You Want More?

Unlock productivity, streamline operations, and energize growth.

Request a demo today.