Get On the Technology Bus or Risk Getting Run Over by It.

It’s Your Choice…

Invest in technology and move forward or risk being left behind This is not about cool gadgets or short-term trends – it’s truly about survival. The facilities that embrace technology will be the ones to thrive, blowing the competition out of the water by making things faster, better, and more efficiently. Some experts predict that the ongoing consolidation trend will accelerate and the number of machine shops will drop by up to 50% in the next 10-15 years.

This Feels Different

Manufacturing is no stranger to innovation, heck from the start of the Industrial Revolution to today’s Industry 4.0, there’s been constant change. What feels different now is the pace of change. Things like artificial intelligence (AI), the Internet of Things (IoT), and robotics are being adopted quickly by shops of all shapes and sizes. Many of these technologies, like Production Monitoring, can deliver a return on investment measured in days, not years, making adoption a no-brainer. Those unwilling or unable to adapt to this faster pace of change will be probably be bought out or eventually out of business.

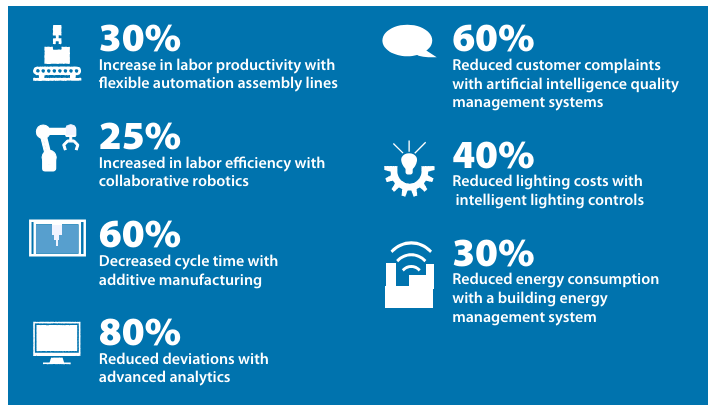

The Power of Technology to Help Manufacturing

What’s driving this acceleration? Chronic labor shortages, reshoring opportunities, and employee retirement are pushing more manufacturers to be open to adopting technology – fast. Here are just a few drivers:

- Efficiency and Productivity: Many automation options streamline production processes, reducing the need for human labor, improving quality, and cutting production times. This can reduce the need to hire more people and makes smaller shops able to compete with larger shops.

- Customization: Advanced 3D-printing makes it easier for shops to produce customized parts at the scale and speed that will drive many “old school” prototype and contract manufacturers out of business. Improvements in material science keep broadening the types of parts and applications that additive manufacturing can address.

- Cost Reduction: Upfront costs for some technologies are high (especially palletized machines & robots) but the long-term benefits are clear. Improving and automating the production process uses fewer human resources, less energy, and minimizes waste.

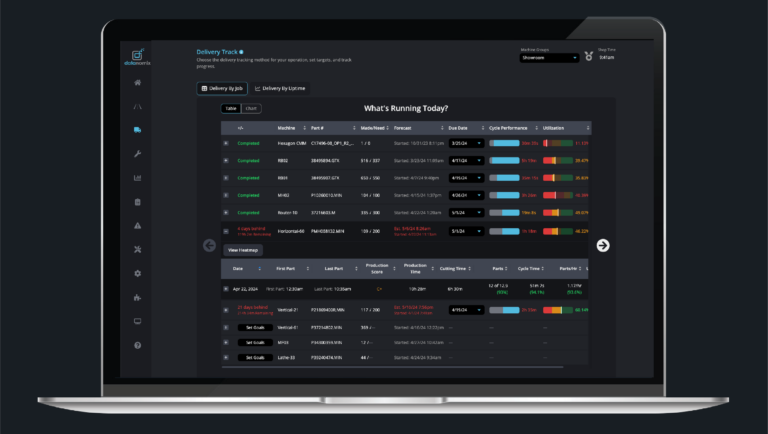

- Data-Driven Decisions: Real-time monitoring of production processes allows people and machines to make immediate adjustments that improve efficiency and reduce downtime.

The Cost of Standing Still

For manufacturers who choose to stick with what they have been doing and reject change, the consequences could be bad. Competitors who invest in technology will be able to deliver better products, faster, and at a lower cost. Remember what happened to US manufacturing back in the 1980s when customers were chasing those same three things? Yeah, it was ugly. Customer expectations for quality, speed, and customization are even higher now.

Technology That Works for You

Embracing technology doesn’t mean throwing out everything that made your buiness successful in the past. And it’s certainly not about replacing people with machines. It’s about making smart investments in technology that will compliment your strengths and give you new capabilities. The key is to start small, learn fast, and scale quickly to make sure you’re one of the survivors.

Technology is Here to Stay

Barring any zombie apocalypse, these advanced technologies are only going to accelerate the rate of change. Investing in technology doesn’t just protect you from the threats of tomorrow, it helps you seize opportunities today. Fortune favors the bold. Be bold. Invest now.