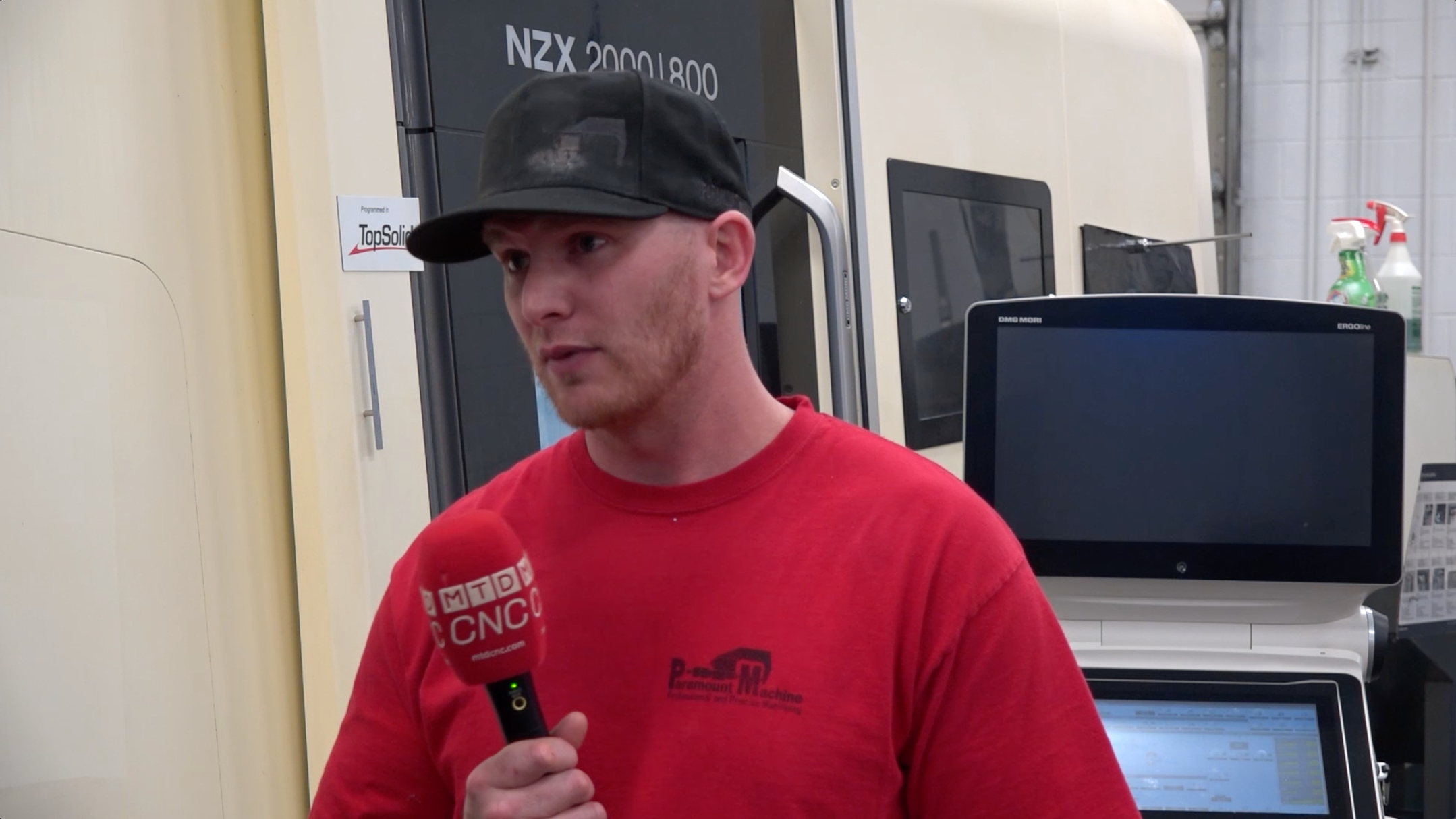

VIDEO: Cutting & Touch Time Data Improves Cycle Times at Busy 50+ Employee Facility

Paramount Machine in Salt Lake City, UT is now able to identify inefficiencies and make necessary improvements thanks to the essential real-time information provided by Datanomix.

Paramount Machine previously tried a different machine monitoring software, but it only provided information that required further analysis to identify areas for improvement. Datanomix, on the other hand, put the information front and center – with no need to assemble, export, or crunch data.

“With Datamomix, it puts that information in front of us, plain and simple. We can just look at it and identify where to focus. We don’t need to hire somebody and incur the cost to have them translate it for us.”

— Devon Gray, Machinist, Paramount Machine

By switching to Datanomix, Paramount Machine can now capture important information for their programmers and operators to improve on cycle times and identify inefficiencies to make necessary improvements.

“Datanomix gives important information back to our programmers and our operators to improve on cycles. With that, it allows them to think of better ways to take time off parts.”

— Devon Gray, Machinist, Paramount Machine

Watch the video with MTDCNC and Devon Gray to learn how Paramount Machine improved cycle times, tool times, and performance with a software system designed specifically for real-time production monitoring.