Is Your Production Monitoring System Next-Gen?

Not all production monitoring is created equal.

For today’s manufacturers, running the business with data is critical to fully understanding operations, increasing productivity, and maximizing profitability. As part of a data-driven strategy, forward-thinking manufacturers turn to production monitoring to provide the insights needed to drive decisions based on data and, in short, to stay competitive in a fast-moving marketplace.

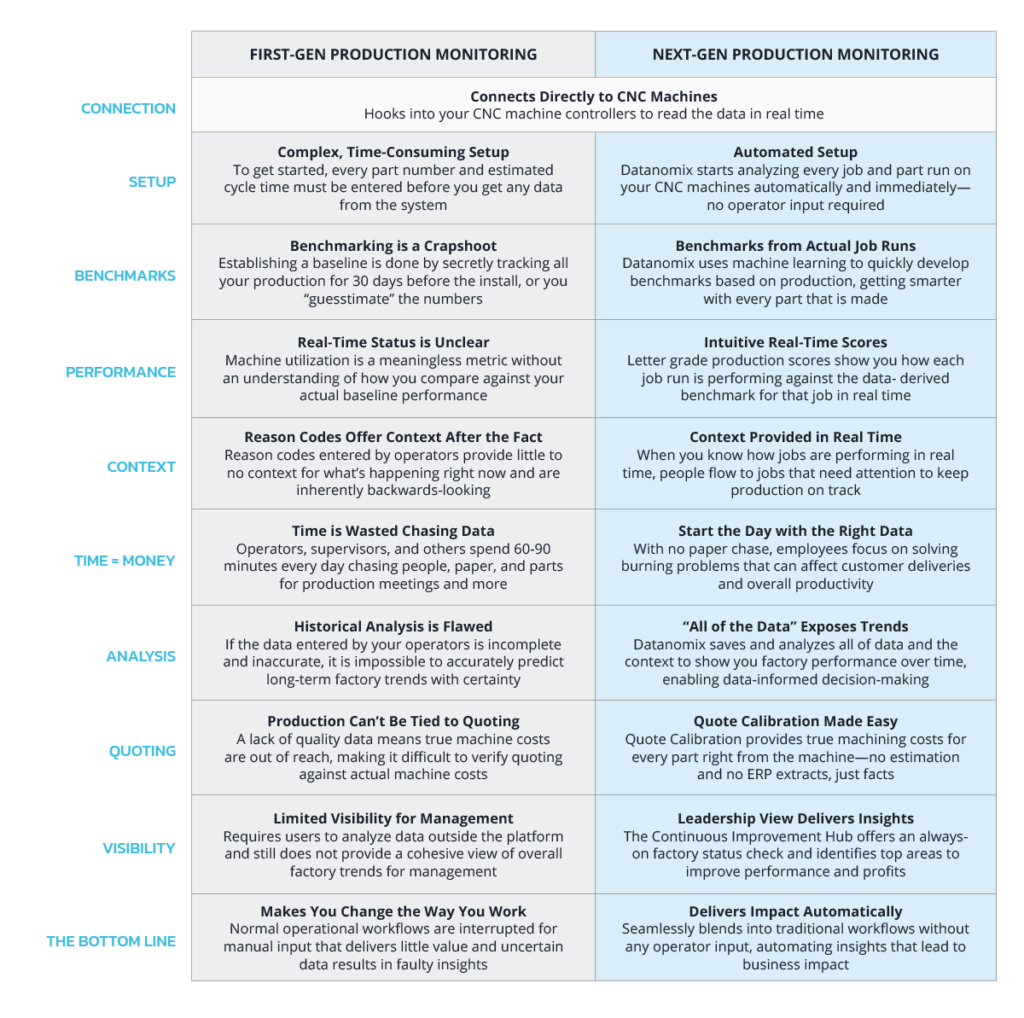

But not all production monitoring is created equal. First-generation solutions have failed manufacturers with labor-intensive setup and operation. They offer little contextual understanding beyond machine utilization and cycle times. In short, first-gen monitoring asks you to change how you work.

In sharp contrast, Datanomix took the time to learn how manufacturers want to use data and automate the work for you. Datanomix offers next-generation production monitoring designed from the ground up to accelerate how you work through advanced analytics and machine learning that automates deep production insights in real-time—No Operator Input™ is required.

Get More from Your Factory with Datanomix

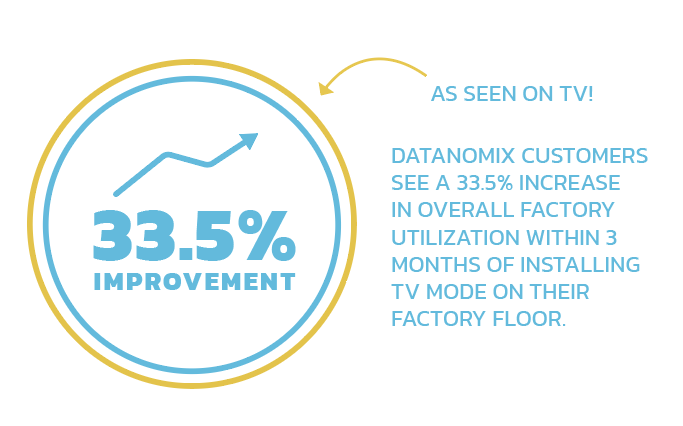

With next-generation production monitoring from Datanomix, our customers experience increased business across the board. In an analysis of our top customers, overall Factory improvement increased by 33.5% after installing Datanomix TV mode on their factory floor. That means your machines run more of the time, cranking out more parts and making more money for your factory.

Want More Info? Check Out Our CTO’s Think Piece!

First-generation production monitoring systems don’t work as intended. Read our think piece and learn how to break free from Mediocre monitoring.