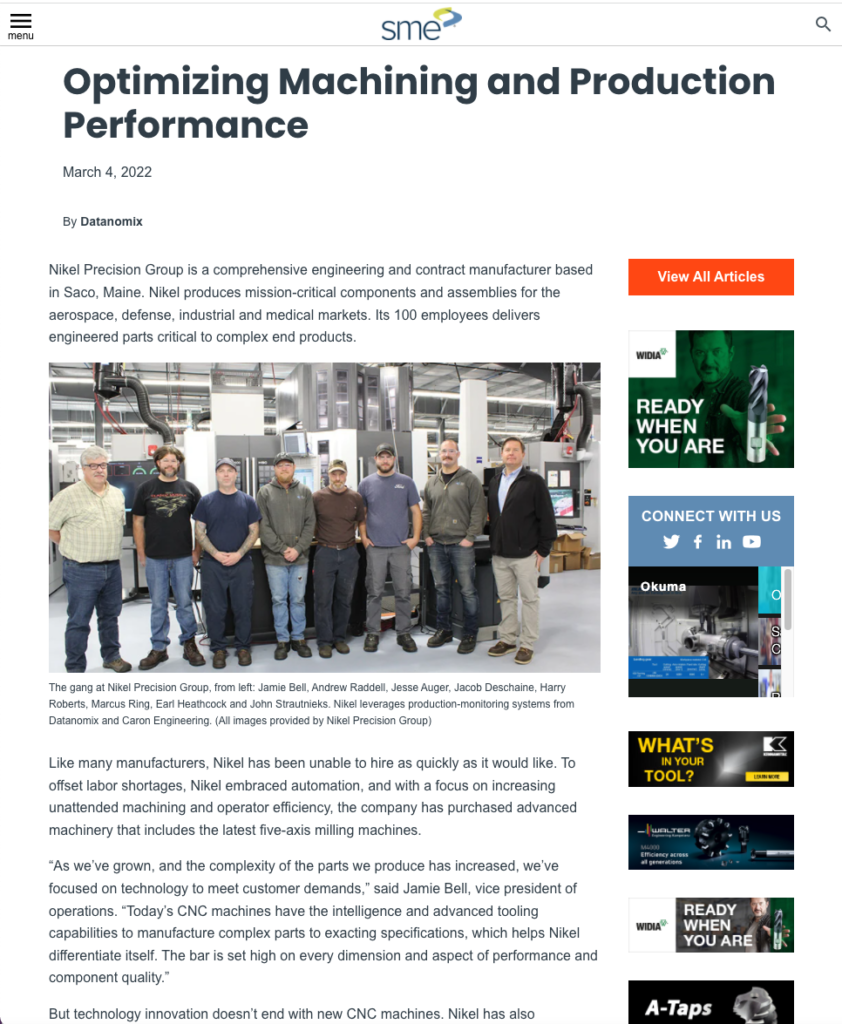

Nikel Precision is Optimizing Machining and Production Performance

Implement solutions that optimize tool performance to improve quality and production intelligence.

Like many manufacturers, Nikel has been unable to hire as quickly as it would like. To offset labor shortages, Nikel embraced automation. With a focus on increasing unattended machining and operator efficiency, the company has purchased advanced machinery that includes the latest five-axis milling machines.

“As we’ve grown, and the complexity of the parts we produce has increased, we’ve focused on technology to meet customer demands,” said Jamie Bell, vice president of operations. “Today’s CNC machines have the intelligence and advanced tooling capabilities to manufacture complex parts to exacting specifications, which helps Nikel differentiate itself. The bar is set high on every dimension and aspect of performance and component quality.”

But technology innovation doesn’t end with new CNC machines. Nikel has also implemented solutions that optimize tool performance to improve quality, as well as production intelligence that provides real-time insights into the performance of the factory.

“Since Datanomix requires no operator input to deliver insights in real-time, the platform supports our strategic initiatives for automation and unattended operation. We get insights automatically.”

— Jamie Bell, Vice President of Operations, Nikel Precision