Just What the Doctor Ordered—Why Medical Manufacturers Need Next-Gen Production Monitoring

Next-gen production monitoring from Datanomix helps manufacturers who make medical devices or components by eliminating the existing methods of collecting, analyzing, and visualizing operational data from CNC machines.

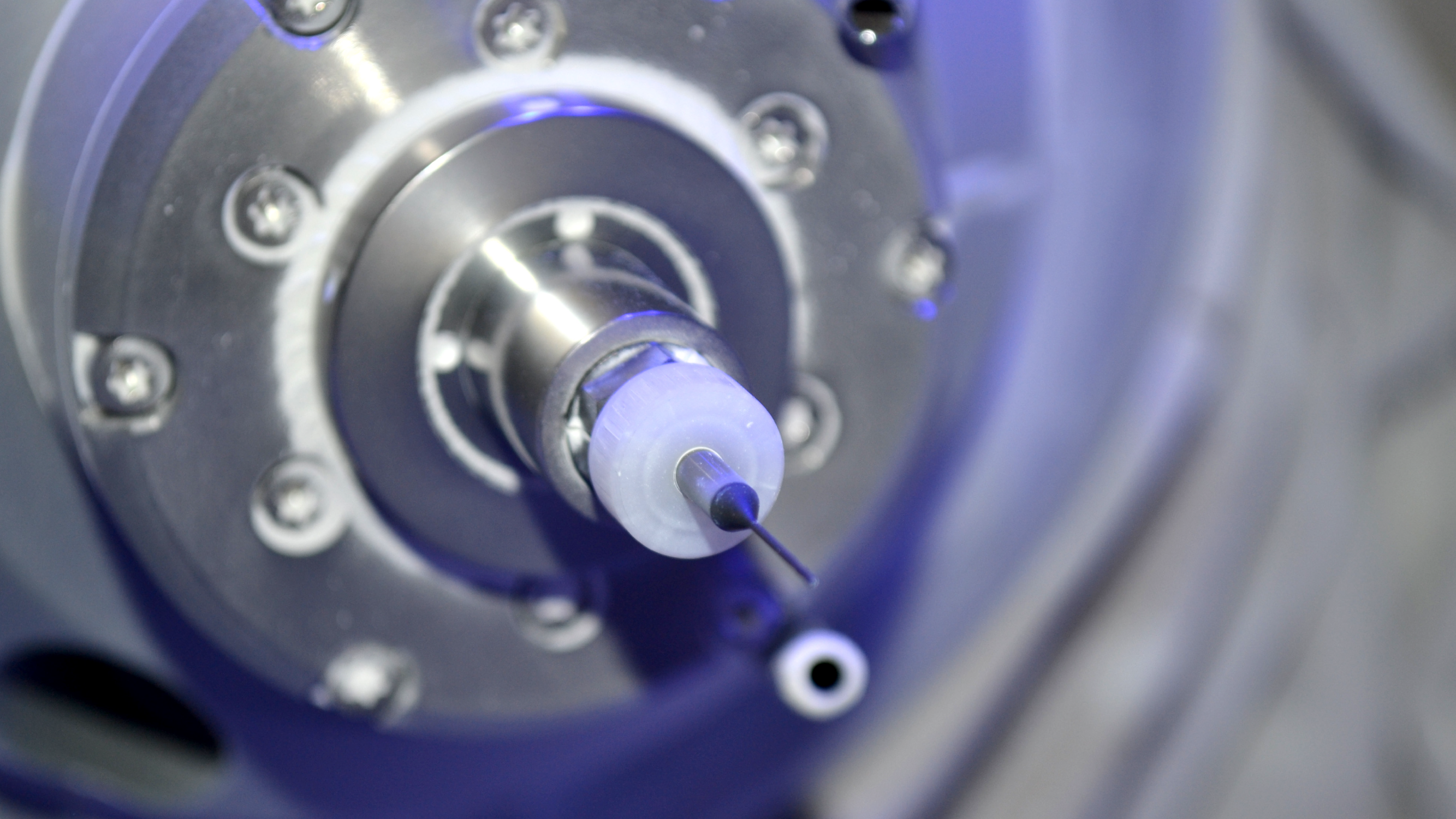

Every precision manufacturer wants to understand more about their operations to make data-driven decisions that help increase productivity, improve quality, and raise profits. For the manufacturers supporting the medical industry, turning out high-quality parts saves lives and affects patient outcomes. There’s no room for latency and human error, which is especially true regarding data collection and analysis of production performance.

Some factory owners still use handwritten logs, ERP systems, and first-generation production monitoring to collect and analyze details of daily operations. It’s not efficient or sustainable to work that way. And any form of operator input to measure productivity is fraught with challenges, including accidental errors.

It’s time to eliminate the existing methods of collecting, analyzing, and visualizing operational data from CNC machines. If you’re waiting to see production results from yesterday, you’re missing out on an opportunity to make real-time decisions regarding day-to-day performance monitoring.

Manufacturers across industries want to understand production as it’s happening, not after the fact. Instead of just “monitoring,” they need Automated Production Intelligence™ from Datanomix. Also referred to as next-gen production monitoring, Datanomix offers real-time analytics into manufacturing production and provides deeper insights over time.

Here’s how next-gen production monitoring from Datanomix helps while manufacturing medical devices or components:

Visibility Into Job Performance

To improve any process or system, you must first understand where you are right now. Datanomix makes monitoring easy by providing the performance capability for every job with No Operator Input™. Cycle times, Takt parts, machine utilization, downtime, alarms, and other vital metrics are tracked in real-time. The platform assigns a production score from A+ to C- from this machine data for every job. This score is displayed on large-screen TVs around the shop floor, showing everyone an easy-to-understand status for all jobs. And for poorly performing jobs, experienced operators naturally flow to any challenges to get production back on track and profitable.

Datanomix makes it easy for Elos MedTech, a manufacturer based in Memphis, Tennessee, to interpret the daily operations of the machines in the Datanomix cell with information and insights purpose-built to address the data needs of manufacturers. Tim Martin, engineering manager at Elos, said, “It’s easy to ensure our machines are utilized the way they should be. With Datanomix, we see if we’re getting the part counts we need and if the cycle times are where they should be. We identify issues quickly and communicate with the operators to uncover the issue, such as an extra brush detail, an issue with the machine, or if there’s a need for additional training.”

Improve Processes with Data

Understanding historical trends and analyzing performance across the entire job—and over multiple machines, shifts, and days—provides essential insights into how well a shift is performing. By digging into the data, you’ll quickly determine whether performance issues are attributed to personnel, equipment, or the process itself. Many Datanomix customers have found bottlenecks in long-running jobs that they can improve based on understanding delays and stoppages in production.

By identifying bottlenecks in their production workflows, M&H Engineering in Danvers, Massachusetts, can focus on the jobs and processes that need attention, especially from an engineering perspective. “Some of our jobs have been running for 10 – 15 years, and the processes can be a bit outdated,” said Chris Burns, vice president of business development. “Datanomix helps us quickly and efficiently identify the jobs that engineering needs to retool so we can improve the machining process. It’s a huge differentiator because efficiencies are everything, especially as it’s become harder to hire, and we look to use automation to take up the slack.”

Keep Track of Information

Datanomix collects all of the data generated by CNC machines through out-of-the-box workflows and reports that align with how manufacturers already work. When management understands how jobs and people perform, making decisions around capital, job costing, and personnel is easier.

Nikel Precision, based in Saco, Maine, is excited about the opportunities to turn more of the data from their systems into actionable insights, especially around the convergence of people and machines. “Datanomix helps us focus on the things that need focus,” said Jamie Bell, vice president of operations at Nikel Precision. “Today, I can look at the dashboard, and you see that machine A is running at 68% and machine B is running at 98%, and they’re both running the same part. What quickly becomes obvious is machine utilization and efficiency have a lot to do with the guy running the machine. With Datanomix, we can identify these gaps and work out a plan to address them, including training on best practices.”

Better Job Costing

Because the Datanomix platform calculates machine costs for every job, manufacturers have an established basis for improving job costing. The Datanomix Quote Calibration report shows the actual cost of production, the potential cost, and the overall opportunity for increased profitability.

“When we price our jobs, we always use data from past jobs to make sure we get the margins we need to be successful,” said Craig Michaud, director of engineering at ARCH Medical in Seabrook, New Hampshire. “When the job is not as profitable as we like, we go back and analyze whether it was a machine issue, the process was bad, or we just made a mistake on the quote. Having all of the operational data from Datanomix—cycle times, utilization, alarm codes, and more—gives us deeper insights into every job so we can be more efficient when we quote.”

Datanomix is a Trusted Provider for Medical Manufacturers

Medical manufacturing needs modern solutions for collecting, storing, and analyzing data to make the best decisions regarding improving operations. Next-gen solutions like the Datanomix Automated Production Intelligence platform deliver deep insights and real-time operational observations without extracting data and using BI tools or spreadsheets. Instead of data wrangling and crunching, medical manufacturers can focus on their workflows and getting life-saving medical parts out the door.